SCOPE OF WORK

Pre Engineering Pipeline Survey Offshore Cameroon

Marine Survey for pipeline route design and engineering

Lighthouse was engaged to carry out a marine survey for a pipeline route to determine the suitability of the proposed routes and to identify any geological and topographical conditions which could impair pipeline lay and associated burial operations.

Preparation and Vessel Mobilization

The vessel and the instrument needed to complete the various phases of the survey where mobilised and tested in Italy.

A HSE plan for the project was prepared and put in action, being aware that the area is well known for the presence of piracy.

Work Phases

In order fulfil the scope of work and to gather all the information useful to the customer the survey was split into different phases:

- 2D Ultra High Resolution Seismic survey.

- Pipeline routes corridor bathymetric and geophysical survey by means of MBES, SBES, SSS, SBP and magnetometer.

- Pipeline routes geotechnical characterization by means of vibrocorer and laboratory analysis.

- Pipeline routes environmental survey to characterize biologic chemical and physical properties of seabed and waters.

- Data processing, final charting and reporting.

QUICK FACT

The project consisted in a main pipeline route with additional spurlines for a total length of 280 Km. More than 3300 km were surveyed.

METHODOLOGIES

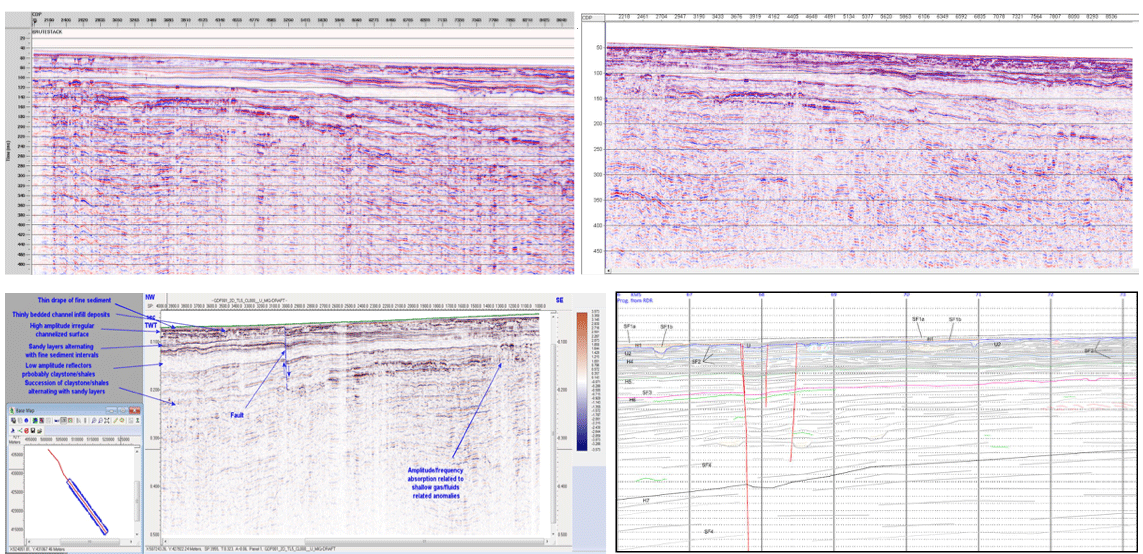

- 2D Ultra High Resolution Seismic survey

The 2DUHR Seismic survey was performed to detect possible hazard in the shallow stratigraphy for the pipelines routes.

The main challenge was to provide to Costumer all the needed information in the expected deadlines in order to proceed with the following phases of the survey. All the acquired data passed though the Quality Control (QC), and were processed and finally interpreted on board. A preliminary interpretation was provided before the start of the geophysical survey (24 hours after the end of the last acquired line), while the final interpretation was provided at the end of the geophysical survey.

2D Ultra High Resolution QC, Processing, Interpretation steps

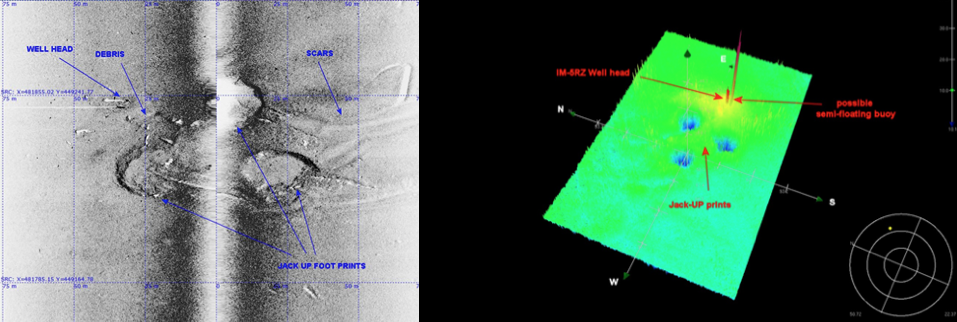

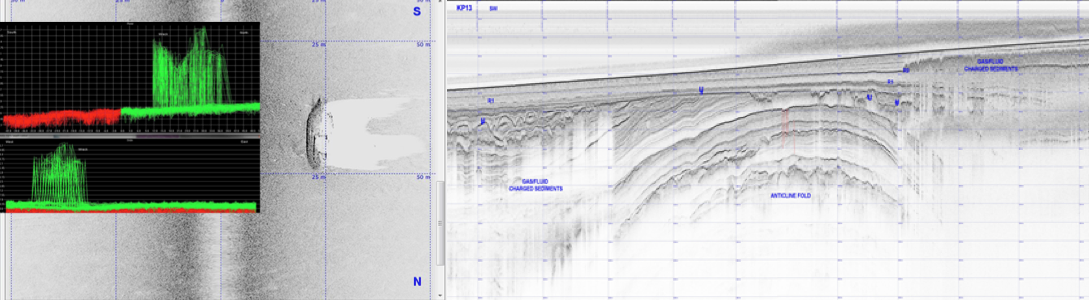

- Pipeline routes corridor bathymetric and geophysical survey

Once the Pipeline Routes were chosen the whole corridor was investigated in order to detect any possible hazard for the future pipeline lay. The main challenge was to provide to Costumer all the needed information in the expected deadlines, to immediately warn them in case of major hazards, in order to give them the possibility to modify the route. Finally the station for Geotechnical and environmental survey had to be chosen according to the geophysical results.

Multibeam, Side Scan Sonar and Sub Bottom Profiler Data Examples

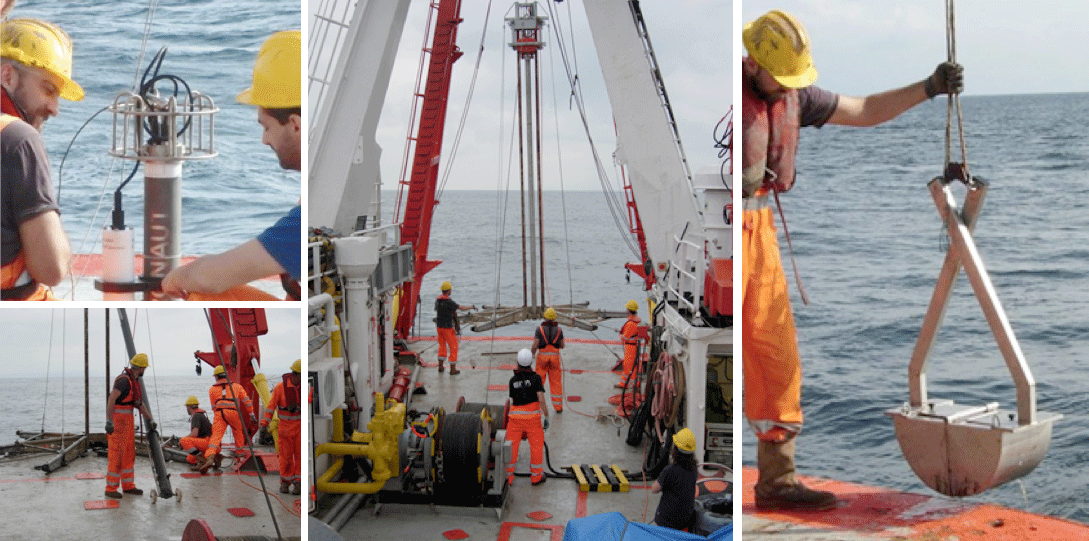

- Pipeline routes geotechnical and environmental surveys

Once the geophysical phase was completed the sampling stations were chosen and the vessel performed a campaign of geotechnical and environmental tests. The main challenge was to complete within the expected deadlines the surveys, to store in the proper way all the samples and to optimize the logistic for the samples analysis.

Geotechnical and Environmental sampling operations

- Final charting and reporting

Once the survey operations were completed and all the data were gathered, they were combined and the results were presented in their final from, through reports and alignment sheet charts.

Quality, Health, Safety and Environment

In course of the project Lighthouse implemented a series of measures to maintain high level of safety on board.

Personnel were following the guidelines of company HSE Management System, bridged with Client’s requirements by project-specific HSE Plan, Emergency Response Plan and a Risk Assessment, that identified potential project risks and ensured that the level of exposure is kept ALARP. No violations were recorded.

In general, every attempt was made to comply with industry’s best practice.

Project Duration

The project lasted 10 months, from January to November 2014. This included the Survey preparation and mobilisation of the vessel (from January to April); the different phases of the Survey (from April to July) and the final data charting and reporting, which included a detailed geotechnical and environmental samples analysis, as required by the Customer (from August to November).

The Vessel

For this Survey we chose to employ our R/V Odin Finder, a 50 m long research vessel, owned by Lighthouse since 2001.

The vessel has performed most of our surveys worldwide, proving her reliability and fitness to the survey operations. Being dynamically positioned, fully permanently mobilized with geophysical and geotechnical equipment, Odin Finder represents the best survey platform for a wide range of services. The survey and the processing rooms are large and fitted with all the necessary facilities for the acquisition and processing of the survey data.

Equipment on board

- Primary Positioning system: DGPS C-Nav 3050

- Secondary Positioning system: DGPS C-Nav 1010R

- Gyrocompass/Motion Reference Unit: GEM Polaris FOG-200

- Gyrocompass/ Motion Reference Unit: Teledyne TSS MAHRS

- SVP Probe: Valeport

- Navigation Software: QPS QINSy 8.0

- Bathymetric System: R2 Sonic 2024

- Bathymetric System: L3 ELAC Nautik Seabeam3030

- Sub-bottom Profiler System: Teledyne Benthos Chirp III

- Underwater Positioning: Applied Acoustics-Easytrak Lite

- Single beam Echo sounder: NAVISOUND 215 (hull mounted)

- Hydrofone Array: Sercel SEAL Streamer

- Recording System: Sercel SEAL 408 Recording System

- Seismic Source: Sercel Ming G Gun

- QC and Processing System: Promax 2D

- Water Sampling: NISKIN

- Multi-parameter probe: Idronaut Probe

- Bottom Coring: Geo Vibro corer 6000

- Bottom Sampling: Van veen Grab